The need to control the generation of renewable plants while guaranteeing the stability of the electrical system makes the use of a Power Plant Controller (PPC) indispensable. In addition, it should be noted that:

- Each country and/or Transmission System Operator (TSO) has a different grid code specifying the requirements for interconnecting a generation plant to the power system.

- Each plant may have different controllable elements, such as inverters, wind turbines, batteries, STATCOMs, capacitor banks, tap changers, etc.

- Each plant may have different equipment manufacturers and communication protocols than other plants, and there may even be differences within the same plant.

- Each customer may require special extra functionalities.

All this variability of plants makes it necessary to have a flexible and homogeneous PPC that adapts to the needs of each customer supported by a highly qualified team.

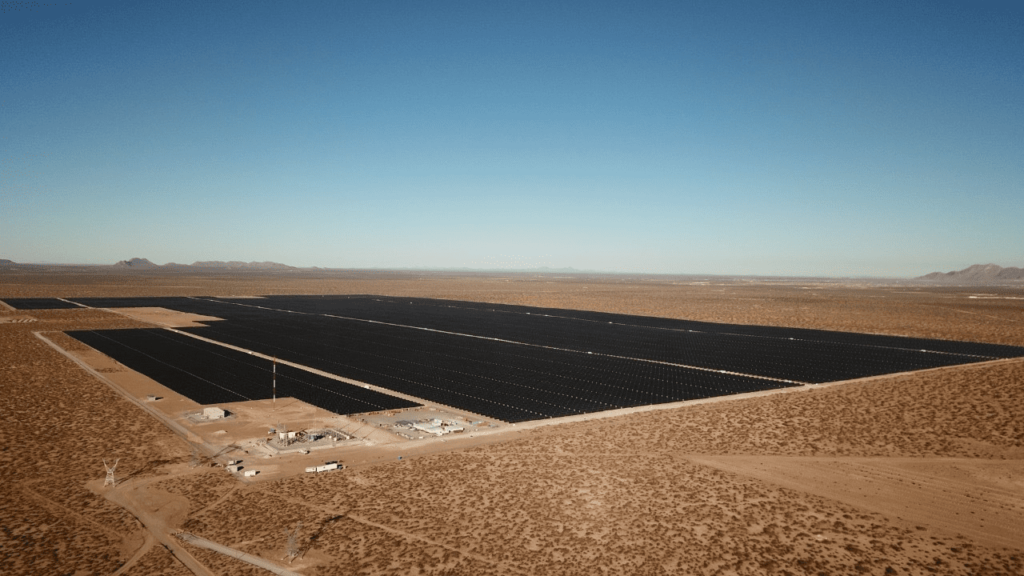

Ingelectus has carried out in the last 4 years the commissioning of more than 20 plant controllers in different countries such as Spain, Mexico, Chile, United States and Canada, with a total power of around 2 GW. Likewise, the Ingelectus team has personnel with more than 10 years of experience in energy control systems.

During these years, the experience has allowed us to develop new functionalities that will help the plant operator during the commissioning and operation of the plant. These new functionalities have not only consisted of changes in the interface, but also in advances within the PPC control logic to adapt to all the casuistry encountered during all these years.

New image and new tools.

Like all technologies applied to the electricity sector, control in renewable generation plants has also evolved significantly in recent years, going from controls with response times of tens of seconds to times of less than a second. Until now, generation plant monitoring systems (SCADAS) have been designed to show the evolution with an accuracy of seconds. However, due to the high response speed of renewable plants, it is necessary to go to resolutions much higher than one second.

In Ingelectus we are aware of how fast the sector is evolving and we have decided to invest to develop a new version of the PPC that adapts to all these requirements to offer a better user experience. Thus, in the new version of PPC we have included a large number of improvements among which stand out:

- New image and organization of the interface to help identify more easily the active controls and alarms.

- Real-time graphics with more than 20 samples per second that allow to know in detail the operation of the plant, even zooming on them.

- Real-time report generation at the push of a button.

- Real-time data download.

In addition to the image and tools improvement, the PPC has been certified for the Spanish NTS 2.1, thus complying with strict requirements for renewable plant control.

Ingelectus PPC has been certified for Spanish NTS 2.1.

Commissioning agility.

Plant commissioning times are crucial for a plant to go into production, that is, for the plant to go into commercial operation (Commercial Operation Date, COD). Every day of delay in receiving COD approval incurs significant economic losses for the customer.

That is why we have developed and implemented in our PPC all the necessary tools to be able to perform a commissioning in the most agile way possible, saving time to the customer thanks to the generation of reports with the behavior of the plant facing different power setpoints.

The reports that can be generated with the PPC interface not only provide value during commissioning. During plant operation, events may occur that need to be studied in depth to ensure the correct behavior of the plant.

These tools also provide other benefits such as the detection and diagnosis of mishaps arising from the daily operation of power plants, such as loss of communication between equipment or lack of response to events. This analysis offers the plant operator the opportunity to correctly identify the source of problems and speed up their resolution.

Plant simulator

Prior to the commissioning of the PPC in the field, at Ingelectus’ offices we have a real-time hardware-in-the-loop (HIL) simulator, fully adaptable to each plant (both at the electrical and communications level). Factory Acceptance Tests (FAT) and a first adjustment of the PPC are performed in this simulator.

Thanks to this simulator, cases can be detected that will save time in the commissioning, avoiding unnecessary set-ups in the plant.

Intelectus has a real-time plant simulator to improve effectiveness.

In Ingelectus we are committed to the generation of clean energy by offering the latest technology and tools to help the installation of new renewable generation plants in the shortest possible time. If you are interested and want more information about our PPC, please contact us: [email protected]